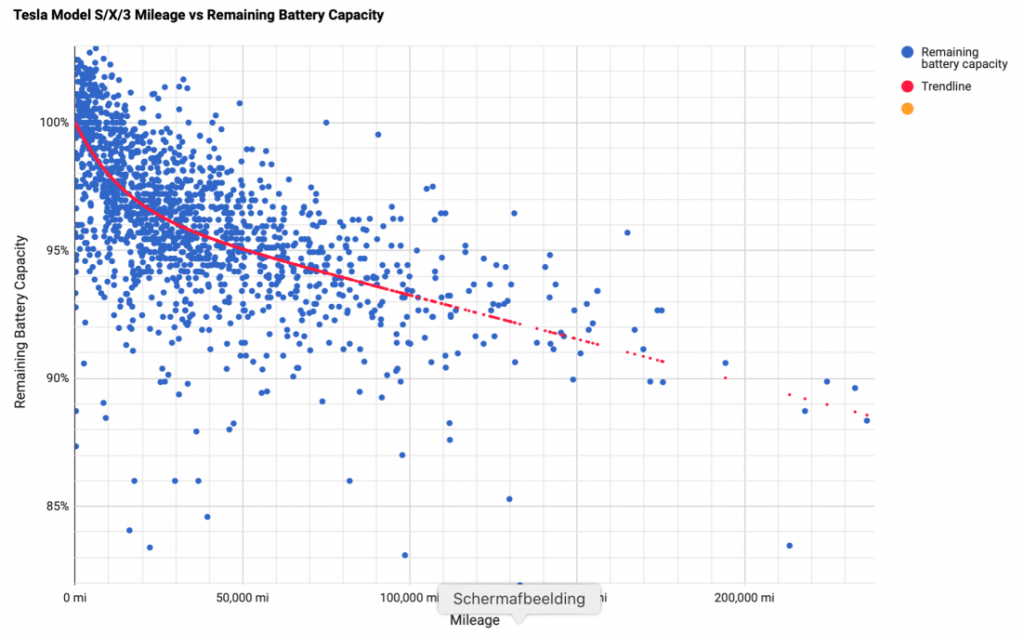

Unlike ICEs, which can run for many decades, EV batteries have limited lifespans, which depend on how the battery is charged, driving habits and temperature extremes. The graph below (source) shows an example of how Remaining Battery Capacity reduces versus number of driven miles for a particular car brand and model.

It is not surprising that an EV battery will degrade over time. After all, it is a sealed, wet, chemical reactor on wheels that does not allow for any form of maintenance. Due to irreversible, dissipative processes in chemical reactions, it can only degrade and can only be replaced. The red trendline is therefore obvious and obviously will change based on who manufactures the battery.

What is surprising is the extremely high scatter even after a few tens of thousands of miles. In the plot above, residual life of the battery can be well below 85% after just 15.000 miles! Even a new battery can have a remaining capacity of less than 90%. What this means is that each battery is quite unique, even when produced at the same manufacturing plant.

What this also means is that running expensive, long-term durability tests on EV batteries is disputable. You never know what battery you’re testing – a lucky one or an unlucky one? You would need to test thousands of batteries to get reliable and in any case highly scattered results. Besides, testing anything on a proving ground is rarely close to real life conditions. Just think of car crash tests.

It would be nice if there were a way to actually measure the real, residual life (or remaining capacity) of a battery in real time, onboard every car. Well, there is.

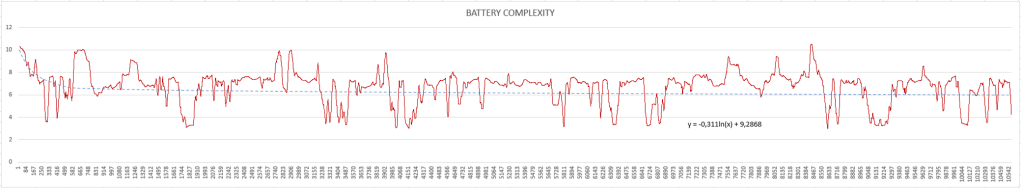

We have recently analyzed EV battery data from a battery durability test. The data spanned approximately ten days, and included: State of Charge, Current, Voltage and Temperature. We computed the corresponding complexity with the same frequency with which the data is obtained, i.e. once a minute.

But what has complexity got to do with battery residual life? Complexity is a systemic measure of overall activity and State of Health. A system that slowly becomes less complex is less ‘lively’. This is what happens when people age. Loss of functionality or simply degradation, is reflected in progressive complexity reduction. The same happens to EV batteries. Below is the time history of the complexity of the mentioned EV battery (click image to enlarge).

The dashed blue line shows the complexity trend. The equation is this:

where x is time.

What this equation shows is a slow, progressive reduction in mean value. For example, the mean will be reduced to 50% of its initial value in around 700 days (just under two years). This is the rate of residual life reduction. Again, it can be measured in real time and onboard any EV. It is very simple to incorporate the underlying QCM software in any Battery Management System.

The equation can be updated, even in real time. If one changes charging or driving habits, the equation won’t stay the same. This means that one may take into account the effective history of a specific battery and not rely of stat charts full of outliers.

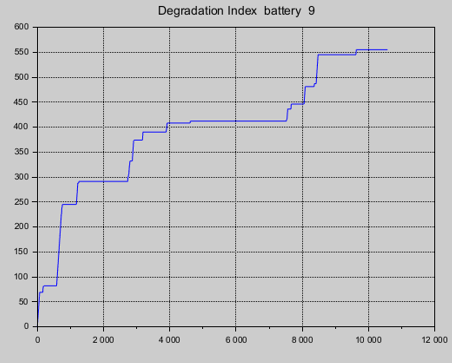

An additional piece of information on the state of health of a battery is the Degradation Index (DI), which is derived from complexity. In the case of the above battery the DI is shown below:

The DI shows that there have been two periods in which degradation has been accelerating significantly. It is easy to display similar information on a dashboard.

At the time of writing, no EV manufacturer is able to provide a driver with similar information. All they show is residual charge and a rough estimate (often a very rough and overly optimistic estimate) of the remaining range.

We think that similar information, which would surely be appreciated by EV owners, will not be displayed on any EV dashboard anytime soon. Why? Because inconvenient truth is not good for marketing, and shareholders don’t like it.

0 comments on “Measuring EV Battery Residual Life in Real Time. Onboard.”