As products become more complex they become more fragile. It is necessary to focus on product robustness by making products less complex. This may be accomplished by using OntoNet™, our QCM Engine.

OntoNet™ allows users to:

- Measure the robustness of a design/component

- Measure the complexity of a design/component

- Identify the drivers of design robustness and complexity

- Perform complexity/robustness-based design by plugging it into a commercial PIDO tool.

OntoNet™ is a first-of-a-kind tool. It processes and adds value to data originating from:

- Monte Carlo Simulation

- DOE, Sensitivity analysis

- Optimization

- Explicit FE code simulation

PROBLEM: Design a pedestrian bridge having prescribed values of

- Mass

- Stiffness (first two frequencies)

- Mid-deck displacement

- Safety factor

… and minimum complexity, i.e. the goal is to determine the simplest design which satisfies constraints and objectives.

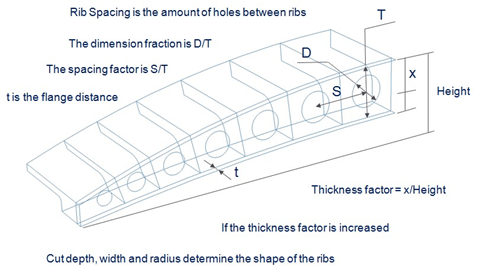

The nominal CAD model is shown below. The design variables are the geometric and topological parameters of the model.

OntoNet™ is plugged into a commercial Process Integration Design Optimization (PIDO) tool which uses design complexity as objective function to be minimized. This requires the following steps:

- Perturb randomly CAD geometry.

- Generate Mesh.

- Run FE Solver.

- Measure design performance, check constraints.

- Continue until lowest complexity is reached.

The above process is illustrated in the figure below:

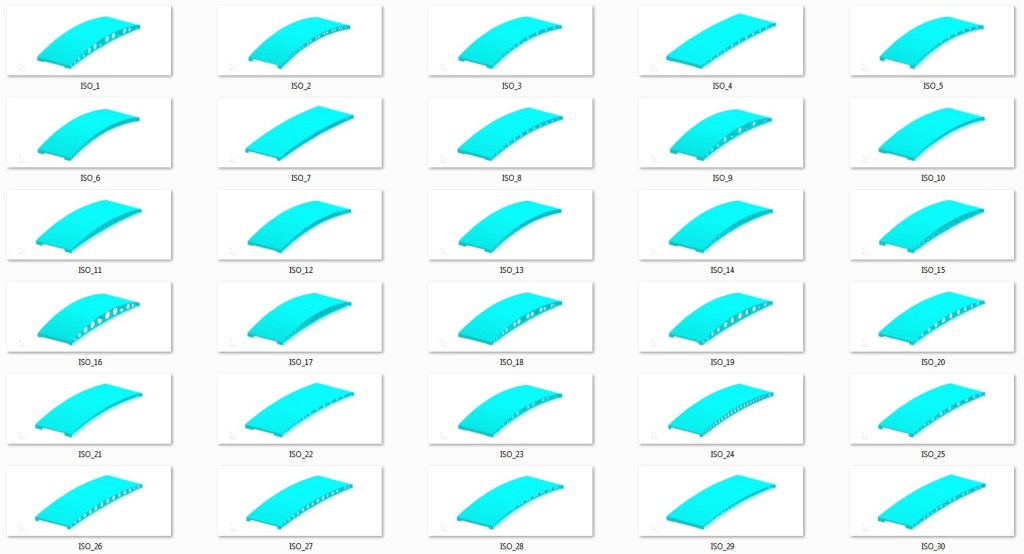

A few hundred iterations are executed, yielding a family of nearly 40 feasible solutions. All satisfy performance requirements and constraints. All have nearly identical performance. Which one is best?

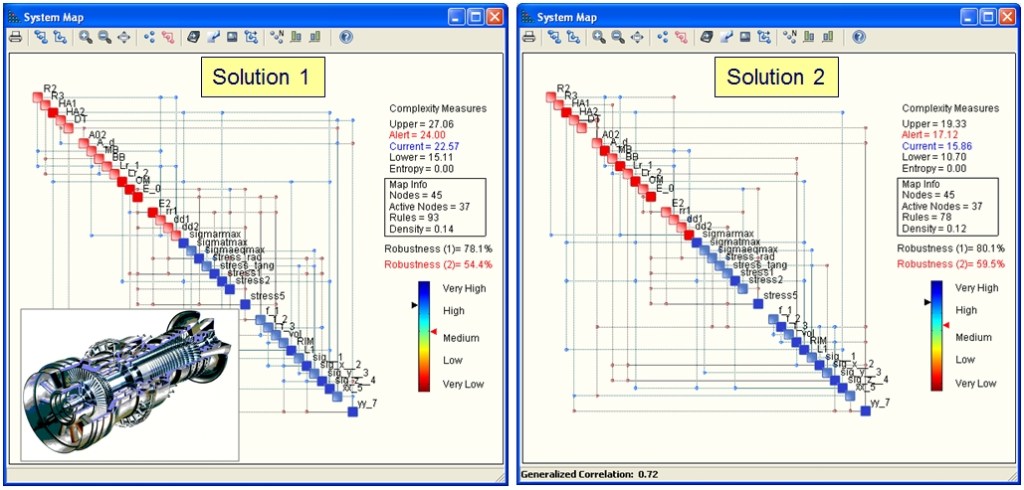

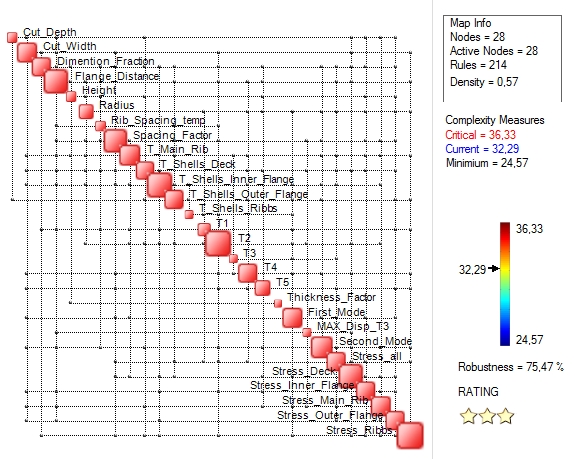

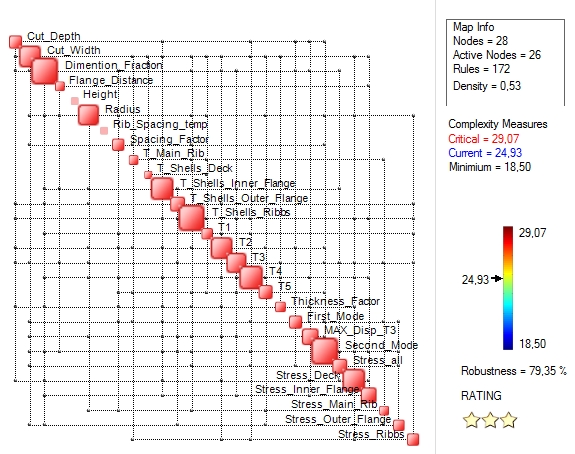

The Complexity Map of the Nominal (initial) design and the Least Complex are shown below.

Nominal Design: complexity = 32.3

Simplest Design: complexity = 24.9. This design is best.

Lower design complexity improves robustness, which increases from 74% to 79%.

All things being equal, the simplest design is the best.

0 comments on “Complexity-based Computer Aided Design”